Ronn,

I always had better luck with a straight fence. It is important to make sure that the blade, the fence, and the table are all aligned properly. The blade and fence must be as parallel as you can get them, and they both must be perpendicular to the table.

Any imperfections in the wood will get translated to the cut. I like to do a light skim sand between cuts if it needs it.

I seriously recommend the Iturra Bladerunner blades (1/2") for your saw. They are thin-kerfed (.032") and cut very well. Also the Woodslicer blades from Highland Hardware in Atlanta are great.

As far as speed, let the blade do the work. Go slowly, and get a feel for when it's cutting well. If it's squeeling, you're wither going too fast, or the blade is getting dull. Don't rush.

Tension of the blade is also important, so make sure you get the blade tension adjusted to blade manufacturer's specs. Too loose, and you'll get a bowed cut....if you need to replace the spring with a high-tension spring, they are available from Iturra Design, or at Woodcraft etc.

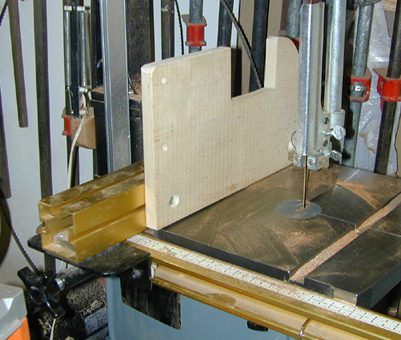

I also recommend using push blocks, and not your hands for feeding the wood into the saw. Blocks like these are great.

Safety first! Wear eye protection and hearing protection if you're running a dust collector too. And a dust mask is important as well.

Don Williams39045.901875

|